Salt Spray Promotion of July 2024

Workshop for Pathumthani workflow re-designing

June 28, 2024

Corrosion Fundamental and Corrosion Testing

August 13, 2024Salt Spray Promotion of July 2024

ALS Promotion of July 2024

Sprecial discount Now – 31 October 2024

Salt Spray Test 1,500 baht

(form 2,500 baht/day)

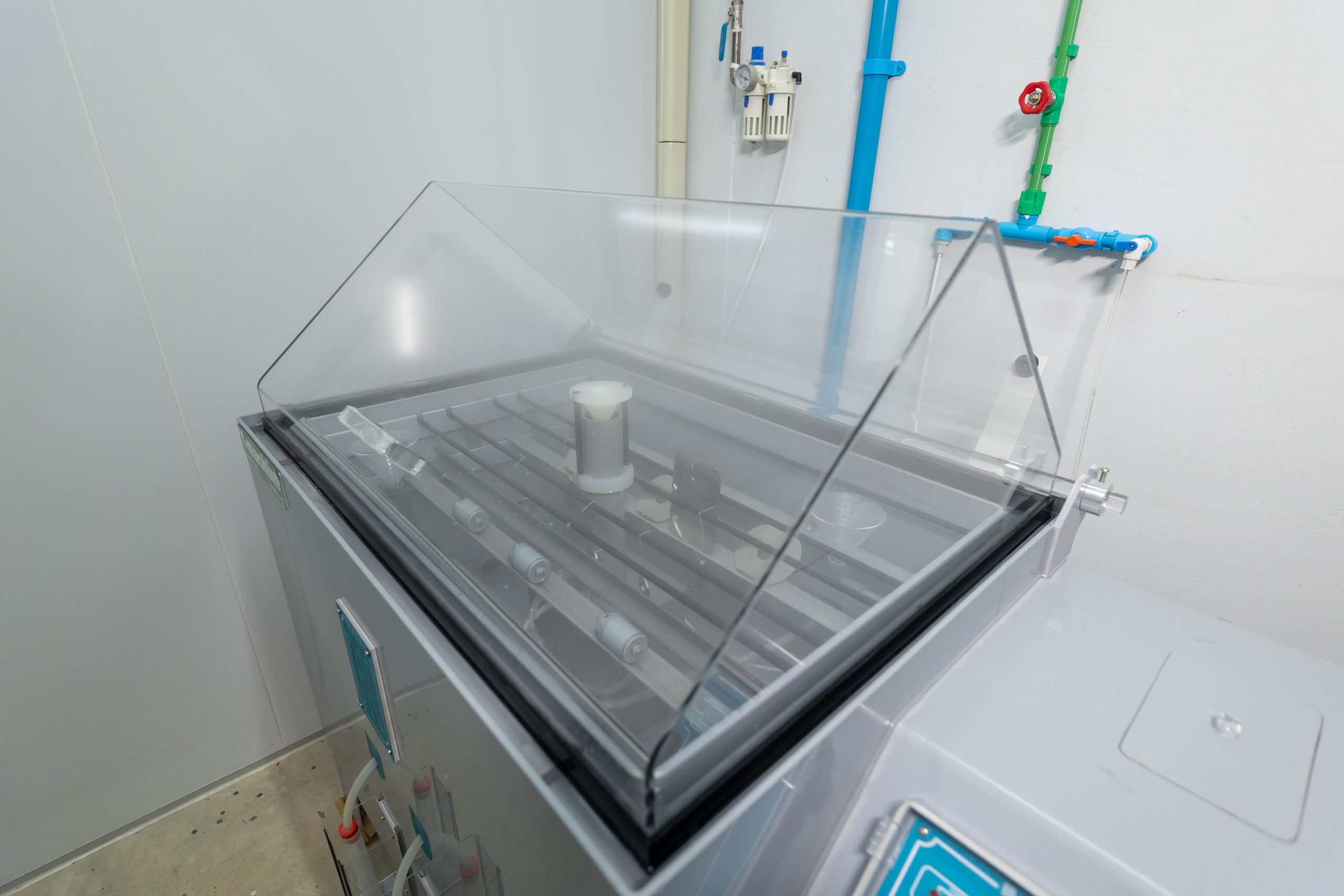

ALS are ready to provide Corrosion test from stimulate salt mist (Sodium Chloride solution) according to reference standard of ASTM B117, JIZ S 2371, IEC 60068-2-52, MIL-STD-202G-101 or standard method according to client request.

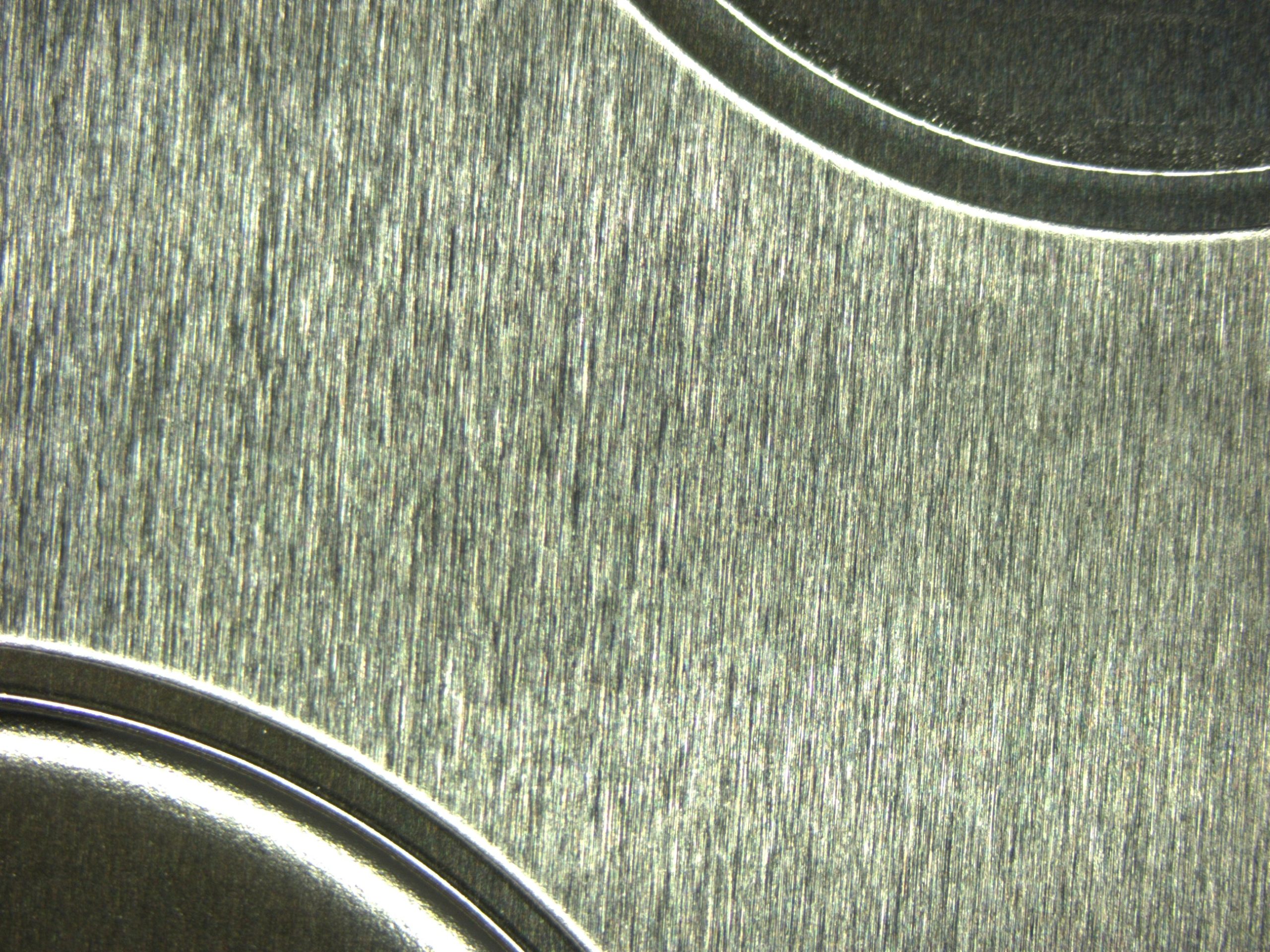

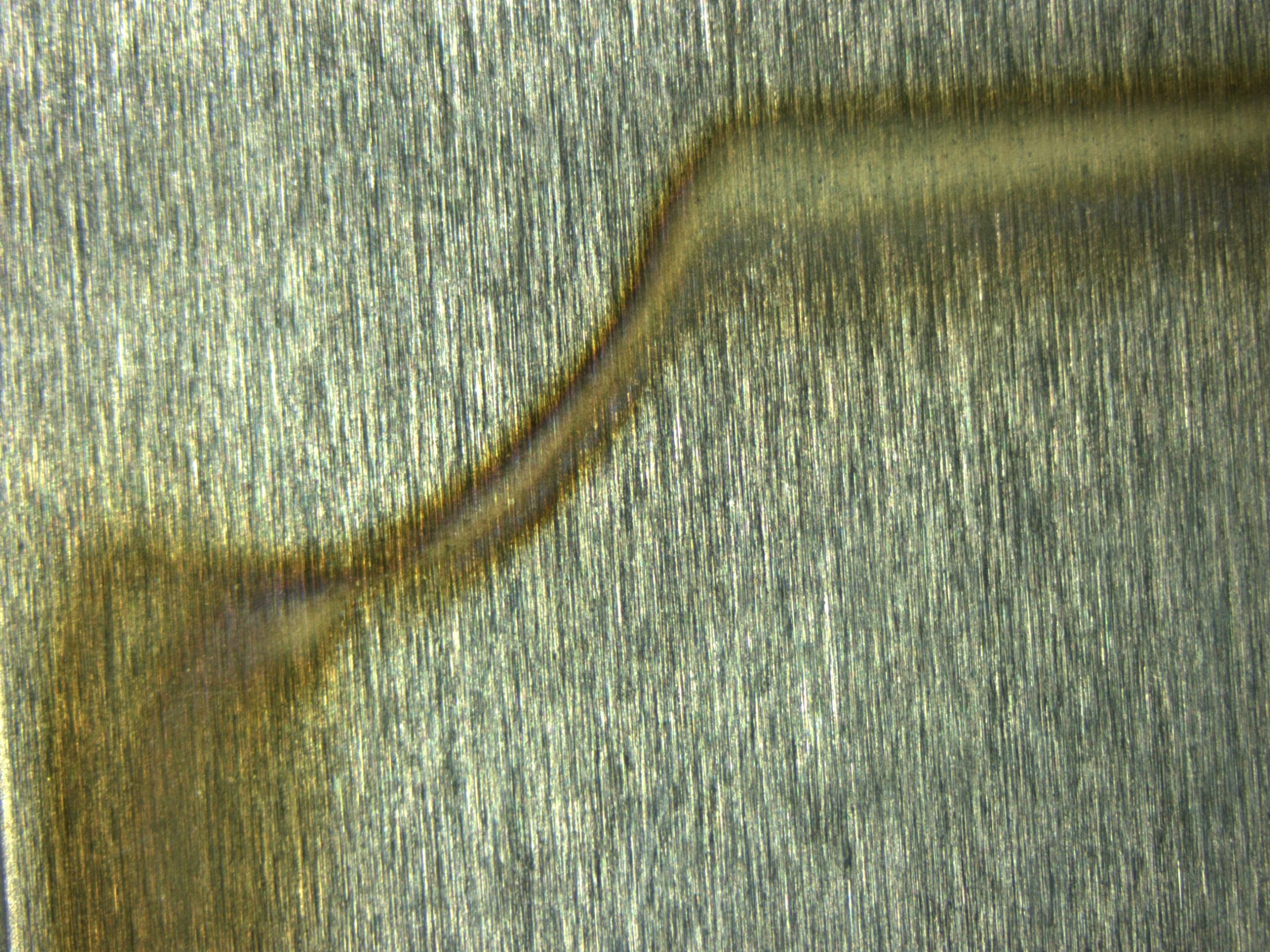

The salt spray test, also known as the salt fog test, is a widely recognized method for evaluating the corrosion resistance of materials and surface coatings.

Purpose and Procedure :

The salt spray test creates an accelerated corrosive environment by subjecting test specimens to a continuous and controlled salt spray mist.

The test evaluates the suitability of coatings as protective finishes by assessing the appearance of corrosion products (such as rust or other oxides) after a predetermined period.

The duration of testing varies based on the corrosion resistance of the coating.

Standards and Recognition:

The ASTM B117 salt spray test is the gold standard for corrosion testing.

It was first published in 1939 and is widely used internationally.

Other relevant standards include JIS Z 2371, IEC 60068-2-52 and MIL-STD-202G-101.

Application:

Salt spray testing is popular due to its low cost, quick results, and standardization.

While it may not directly predict real-world corrosion resistance, it is valuable for quality audits and process control.

For instance, pre-treated + painted components must pass 96 hours of Neutral Salt Spray to be accepted for production.

Remember that the salt spray test provides insights into the durability of materials and coatings under corrosive conditions, allowing for meaningful comparisons.

More information please contact :

- Kamonworanee (Jib) Tel.: +669 4480 4705 E-mail : k.theptaranonth@alsglobal.com

- Hathaikan (A) Tel.: +669 4480 4706 E-mail : Hathaikan.israngkur@alsglobal.com

- Customer Service Tel.: +66 2700 9665 E-mail : pathumthani@alsglobal.com