February 10, 2025

Salt Spray Test : การทดสอบความทนทานต่อการกัดกร่อนในวัสดุ

การทดสอบการกัดกร่อน (Corrosion Test) เป็นกระบวนการที่ใช้เพื่อประเมินความทนทานของวัสดุต่อการกัดกร่อนในสภาวะแวดล้อมต่าง ๆ โดยการกัดกร่อนมักเกิดขึ้นเมื่อวัสดุโดยเฉพาะโลหะทำปฏิกิริยากับสารเคมี เช่น น้ำ ออกซิเจน ก๊าซไอเสีย หรือสารละลายที่เป็นกรดหรือด่าง การทดสอบนี้สำคัญอย่างยิ่งสำหรับอุตสาหกรรมที่ต้องการความมั่นคงและความปลอดภัยในระยะยาว เช่น อุตสาหกรรมการก่อสร้าง การขนส่ง และพลังงาน

วัตถุประสงค์ของการทดสอบการกัดกร่อน

ประเมินอายุการใช้งานของวัสดุ: เพื่อให้ทราบว่าวัสดุจะสามารถใช้งานได้นานแค่ไหนก่อนที่จะเสื่อมสภาพ

เลือกวัสดุที่เหมาะสม: เพื่อเลือกวัสดุที่มีความทนทานต่อสภาวะแวดล้อมเฉพาะ เช่น สภาพกรด-ด่าง ความชื้น หรืออุณหภูมิ

ปรับปรุงกระบวนการผลิต: เพื่อปรับปรุงการเคลือบพื้นผิวหรือการเลือกวัสดุใหม่ที่มีคุณสมบัติที่ดีกว่า

เพิ่มความปลอดภัย: เพื่อป้องกันการเสื่อมสภาพที่อาจนำไปสู่ความเสียหายหรืออันตราย

การทดสอบความทนทานต่อการกัดกร่อนในวัสดุ ( Salt Spray Test )

การทดสอบ Salt Spray หรือการพ่นหมอกเกลือ เป็นกระบวนการที่ใช้ในการประเมินความทนทานของวัสดุจากการกัดกร่อนที่เกิดจากน้ำเกลือ ซึ่งจำลองสภาพแวดล้อมที่มีความชื้นสูงหรือการสัมผัสกับเกลือ โดยเฉพาะในอุตสาหกรรมที่วัสดุต้องเผชิญกับสภาพแวดล้อมที่มีการกัดกร่อนจากเกลือ เช่น ในการผลิตยานยนต์, อุตสาหกรรมการบิน, และการใช้วัสดุในทะเลหรือพื้นที่ที่มีความชื้นสูง

ในบทความนี้จะครอบคลุมถึงวิธีการทดสอบ Salt Spray, มาตรฐานที่ใช้, การตีความผลการทดสอบ, และการประยุกต์ใช้งานในอุตสาหกรรมต่างๆ รวมถึงการดูแลรักษาอุปกรณ์ในการทดสอบ

การทดสอบ Salt Spray คืออะไร?

การทดสอบ Salt Spray คือกระบวนการที่ใช้ในการจำลองสภาพแวดล้อมที่มีเกลือในอากาศ เพื่อตรวจสอบวัสดุหรือชิ้นส่วนต่างๆ ว่าสามารถทนต่อการกัดกร่อนจากเกลือได้หรือไม่ โดยการทดสอบจะทำโดยการฉีดพ่นหมอกเกลือหรือสารละลายเกลือ (NaCl) ลงบนวัสดุที่ต้องการทดสอบในห้องทดสอบที่ควบคุมอุณหภูมิและความชื้นให้เหมาะสม

การทดสอบ Salt Spray สามารถใช้ประเมินความทนทานต่อการกัดกร่อนจากเกลือในระยะยาวและดูความเสื่อมสภาพของวัสดุ เช่น การเกิดสนิมหรือการเปลี่ยนแปลงทางกายภาพของพื้นผิว

วิธีการทดสอบ Salt Spray

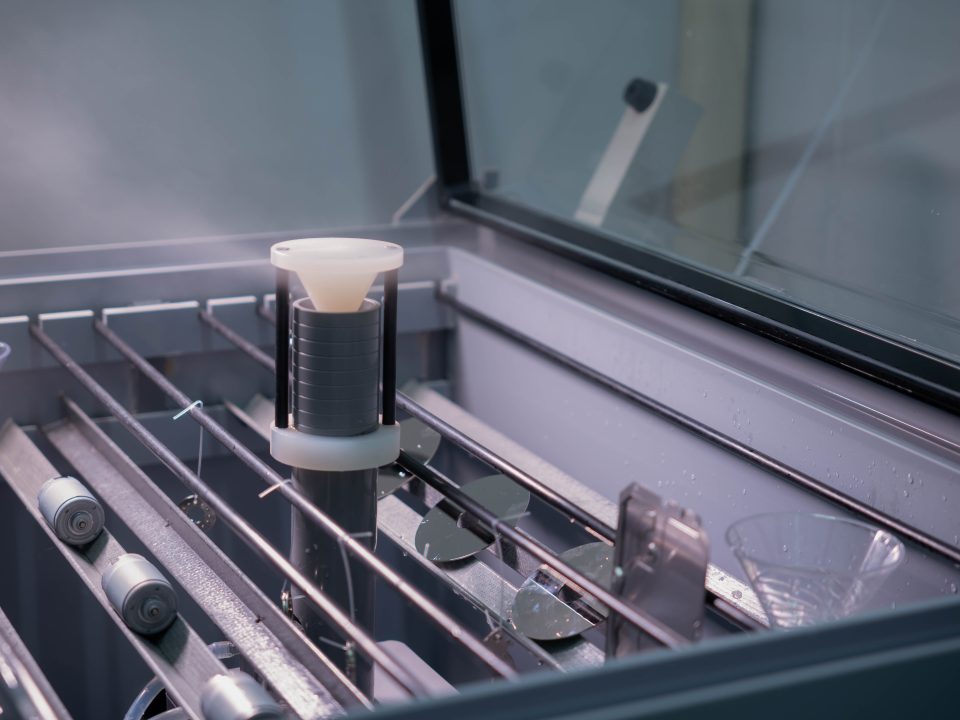

การทดสอบ Salt Spray จะดำเนินการในห้องทดสอบที่ออกแบบมาโดยเฉพาะ โดยในห้องทดสอบนี้จะมีการสร้างสภาพแวดล้อมที่มีความชื้นสูงและอุณหภูมิที่ควบคุมได้ เพื่อจำลองสภาพแวดล้อมที่วัสดุจะต้องเผชิญในชีวิตจริง เช่น พื้นที่ทะเลที่มีการกระทำของเกลือและความชื้นที่สูง

ขั้นตอนการทดสอบ Salt Spray :

การเตรียมตัวอย่าง: วัสดุที่ต้องการทดสอบจะถูกทำความสะอาดและเตรียมให้พร้อมเพื่อให้ผลการทดสอบแม่นยำ

การตั้งค่าห้องทดสอบ: ห้องทดสอบจะถูกตั้งค่าอุณหภูมิและความชื้นที่เหมาะสมตามมาตรฐานที่กำหนด เช่น 35°C และ 95% ความชื้นสัมพัทธ์

การพ่นเกลือ: สารละลาย NaCl จะถูกพ่นลงไปในห้องทดสอบในรูปแบบของหมอกเกลือ โดยจะพ่นจนถึงระยะเวลาที่กำหนด เช่น 48 ชั่วโมงหรือมากกว่า

การตรวจสอบผล: หลังจากเสร็จสิ้นการทดสอบ ตัวอย่างวัสดุจะถูกตรวจสอบเพื่อตรวจหาการเกิดสนิม, การเปลี่ยนแปลงสี, หรือความเสียหายที่เกิดขึ้น

มาตรฐานที่ใช้ในการทดสอบ Salt Spray

ในการทดสอบ Salt Spray มักจะอ้างอิงตามมาตรฐานต่างๆ เพื่อให้ผลการทดสอบมีความถูกต้องและเชื่อถือได้ มาตรฐานที่นิยมใช้มีดังนี้:

ASTM B117: เป็นมาตรฐานที่ใช้กันอย่างแพร่หลายสำหรับการทดสอบ Salt Spray โดยเฉพาะในอุตสาหกรรมยานยนต์และการผลิตชิ้นส่วนโลหะ

ISO 9227: มาตรฐานสากลสำหรับการทดสอบการกัดกร่อนจากเกลือ โดยมักใช้ในอุตสาหกรรมต่างๆ ที่เกี่ยวข้องกับวัสดุก่อสร้างและการผลิตเครื่องมือ

JIS Z 2371: มาตรฐานของญี่ปุ่นที่ใช้สำหรับการทดสอบ Salt Spray ซึ่งมักใช้ในอุตสาหกรรมการผลิตเครื่องจักรและอุปกรณ์

การตีความผลการทดสอบ Salt Spray

ผลจากการทดสอบ Salt Spray สามารถบ่งบอกถึงความทนทานของวัสดุต่อการกัดกร่อนจากสภาพแวดล้อมที่มีเกลือได้ โดยปกติแล้วจะมีการประเมินผลจากการเกิดสนิม, การแตกหัก, การพองตัวของพื้นผิว, หรือการเปลี่ยนแปลงสีของวัสดุที่ทดสอบ

การตีความผลหลักๆ:

การเกิดสนิม: หากวัสดุเริ่มมีสนิมเกิดขึ้นแสดงว่าไม่สามารถทนต่อการกัดกร่อนได้

การเปลี่ยนแปลงสี: วัสดุที่สามารถทนต่อการกัดกร่อนได้จะไม่เปลี่ยนสี

การพองตัวหรือการแตก: วัสดุที่ไม่ทนต่อการกัดกร่อนอาจมีการพองตัวหรือแตกออก

การประยุกต์ใช้งาน Salt Spray Test ในอุตสาหกรรมต่างๆ

การทดสอบ Salt Spray มีการใช้งานในหลากหลายอุตสาหกรรมที่เกี่ยวข้องกับวัสดุที่ต้องทนทานต่อสภาพแวดล้อมที่มีความชื้นหรือเกลือ โดยเฉพาะใน:

อุตสาหกรรมยานยนต์: ใช้ทดสอบชิ้นส่วนต่างๆ เช่น โครงสร้างเหล็ก, โลหะผสม, และชิ้นส่วนภายนอกของรถยนต์ที่ต้องทนต่อสภาพแวดล้อมที่มีเกลือหรือฝน

อุตสาหกรรมการบิน: การทดสอบ Salt Spray ช่วยในการตรวจสอบชิ้นส่วนเครื่องบินที่ต้องทนต่อสภาพอากาศที่มีความชื้นสูง

อุตสาหกรรมทะเล: วัสดุที่ใช้ในงานก่อสร้างหรือการติดตั้งในทะเลจะต้องทนต่อการกัดกร่อนจากเกลือในน้ำทะเล

อุตสาหกรรมก่อสร้าง: ใช้ในการทดสอบวัสดุก่อสร้างที่สัมผัสกับสภาพแวดล้อมที่มีความชื้นสูง

การดูแลรักษาอุปกรณ์ Salt Spray Test

เพื่อให้การทดสอบมีความแม่นยำและได้ผลที่เชื่อถือได้ อุปกรณ์ที่ใช้ในการทดสอบ Salt Spray ควรได้รับการดูแลรักษาอย่างสม่ำเสมอ การทำความสะอาด, การคาลิเบรต, และการตรวจสอบสภาพห้องทดสอบเป็นสิ่งสำคัญในการรักษาความถูกต้องของผลการทดสอบ

สรุป การทดสอบ Salt Spray Test

การทดสอบ Salt Spray เป็นเครื่องมือที่สำคัญในการประเมินความทนทานของวัสดุต่อการกัดกร่อนจากเกลือ โดยเฉพาะในสภาพแวดล้อมที่มีความชื้นสูงหรือเกลือ ซึ่งมีการใช้งานในหลากหลายอุตสาหกรรม เช่น ยานยนต์ การบิน และการก่อสร้าง ในการทดสอบนี้จะมีการใช้มาตรฐานที่ถูกต้องและมีขั้นตอนการทดสอบที่จำเป็นต้องปฏิบัติตามเพื่อให้ได้ผลลัพธ์ที่เชื่อถือได้ และสุดท้ายการดูแลรักษาอุปกรณ์การทดสอบก็เป็นสิ่งสำคัญในการรักษาความแม่นยำในการทดสอบ

บริษัท เอแอลเอส เทสติ้ง เซอร์วิสเซส (ประเทศไทย) จำกัด

Alstesting บริการตรวจสอบสารเคมี ด้วยเทคโนโลยีที่ทันสมัย และทีมผู้เชี่ยวชาญด้านการวิเคราะห์

โทรศัพท์+(66) 2700 9665

อีเมลpathumthani@alsglobal.com

Read moreOctober 12, 2023

ALS Electronics can provide banned substance testing for consumer products to meet international regulations including EU directives 2002/95/EC. Our services cover:

RoHS compliance and other banned substances testing on WEEE

RoHS compliance and other banned substances testing on WEEE

Lead (Pb)

Mercury (Hg)

Cadmium (Cd)

Hexavalent Chromium (Cr(VI))

PBB (Polybrominated Biphenyls)

PBDE (Polybrominated Diphenyl Ethers)

Halogen free testing

Migration metals according to EN71-3 for toy safety

EU banned phthalates

REACH SVHC 16 banned substances

16 Banned PAHs

Read moreOctober 12, 2023

As electronic components get smaller, the need for cleaner parts becomes ever more critical.

Our cleanliness and micro-contaminant testing service can help to improve your components’ reliability.

FT-IR and Microscope FT-IR

Liquid-borne Particle Counter (LPC)

Particle Analyzer as required by Road vehicles – Cleanliness of components and systems (ISO 16232-2018)

Ion Chromatography (IC)

High-Performance Liquid Chromatography (HPLC)

Scanning Electron Microscope with Energy Dispersive X-ray spectroscopy (SEM/EDX)

GC/MS and Thermal Desorption GC/MS

Read moreOctober 12, 2023

To employ various analytical techniques, we can assist customer to diagnose component failures due to contamination and material related issues. We offer Failure Analysis services inclusive of below.

Optical Microscope Examination

Scanning Electron Microscope Examination

Foreign Material Identifications

Micro-metrological measurements including

Step Height Measurement

Flatness Measurement

Roughness Measurement

3D Microscopic Imaging

Microscope FT-IR Analysis

Cross sectional

Read moreOctober 12, 2023

Our Reliability test for electronic components is normally placed the sample in control environment chamber – Temperature, Humidity or Salt mist.

Temperature–humidity cycling

Thermal shock

Chemical compatibility studies

Salt spray chamber

Xenon arc test

Read moreOctober 12, 2023

Nowadays product safety and quality are the two important factor which requires in manufacturing.

It needs area that minimizes the introduction of airborne particles, control temperature, humidity, sound, free ion, bacteria, volatile gases, and etc.

Our field sampling is consisted of.

Ultrapure and DI Water Monitoring

Total Oxidisable Carbon (TOC)

Total Dissolved Silica (SiO2)

Total Bacteria Count

Trace Metals (including Zn, Fe, Cu, Al, Cr, Mn, Pb and Sn)

Ion (F–, Cl–, Br–, NO2–, NO3–, PO43-, SO42-, Li+, Na+, K+, Mg2+, Ca2+, and NH4+)

Cleanroom Air and Clean Dry Air – Volatile Organic Carbon (VOC), Ionics by impinging and Trace metals

Indoor air quality per ISO 16000-40:2019

Read more