Plastic Testing

ISO/IEC 17025 Requirement Internal Training

April 18, 2024

Workshop for Pathumthani workflow re-designing

June 28, 2024Plastic Testing

Experiencing issues with your plastic parts? ALS is here to help!

Are your plastic parts becoming brittle, cracking, or breaking more easily? Is their toughness diminishing? ALS has a range of testing methods to identify the root cause of these abnormalities.

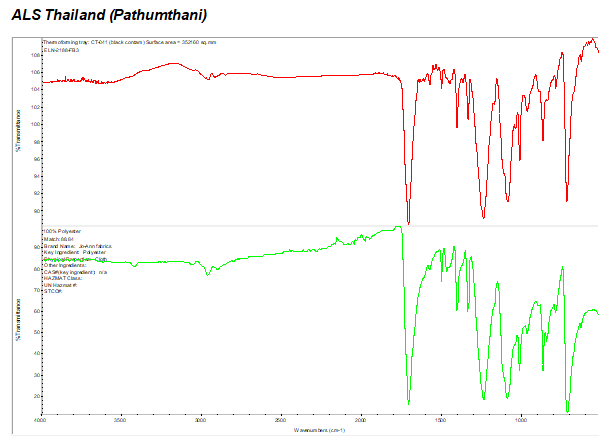

FT-IR Testing

For instance, if the plastic type has been switched,

we can perform FT-IR (Fourier Transform Infrared Spectroscopy)

testing to compare the spectrum with a standard database.

This allows us to classify and confirm the type of plastic used.

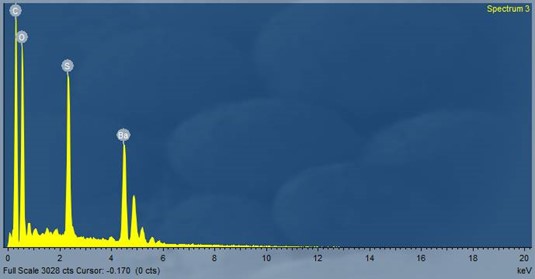

SEM/EDX Analysis

Even if the material is identified as the same type through FT-IR testing, there could be additives introduced to reduce costs, potentially affecting the plastic's properties.

In such cases, SEM/EDX (Scanning Electron Microscopy with Energy Dispersive X-ray Spectroscopy) analysis can be employed to differentiate between normal and problematic parts.

SEM examines the external morphology and structure, while EDX analyzes and identifies the elements present in the plastic.

This combination allows for a comprehensive comparison between affected and normal plastic parts.

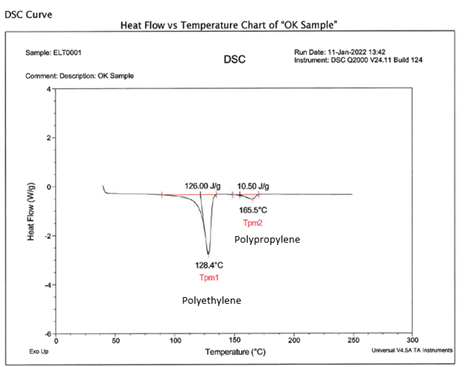

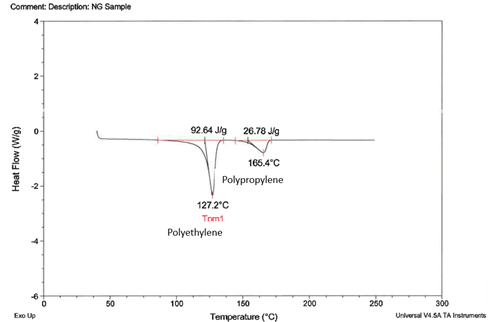

DSC and TGA Testing

If the plastic has a blend of different types of plastics, its characteristics may change.

We utilize DSC (Differential Scanning Calorimetry) and TGA (Thermogravimetric Analysis) to determine the blend ratio and combustion residues, indicating the material's purity.

The example below shows the ratio of Polyethylene and Polypropylene,

followed by SEM/EDX analysis of the residues to identify their type.